“Control options are endless, but the cost of implementation index drops as a function of the complexity of the project.”

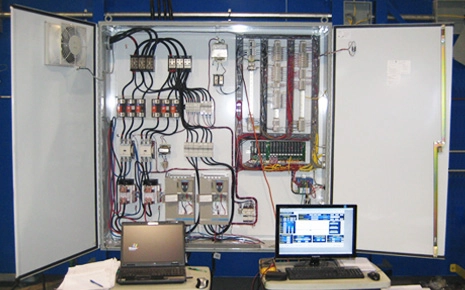

A large part of equipment efficiency concerning industrial ovens, dust collectors or fresh air intake systems is directly linked to the design of control panels.

Team members who specialize in automation and control recommend customized solutions that factor in each equipment, their operating environment and specific needs of the customer. Programming and accessories proposed by our team are designed to provide a perfect balance between system control intelligence and implementation cost.

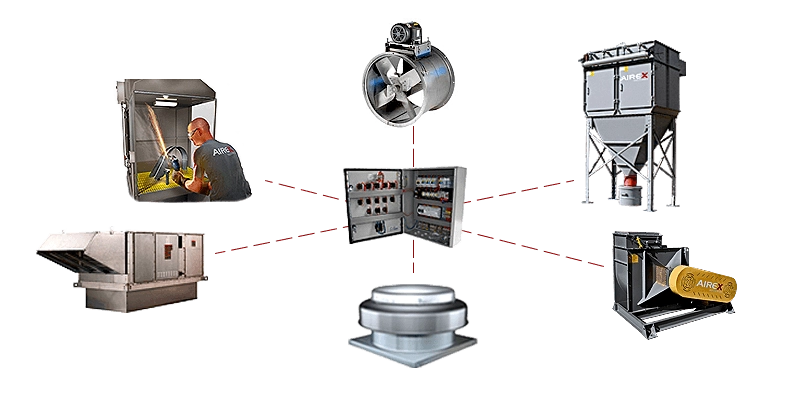

CONTROL CENTRALIZATION

Manufacturing plants with decentralized heating, ventilation and air-conditioning equipment (HVAC) frequently manage each system independently of the others.

Airex has become an expert in centralizing HVAC equipment control by working with industries dealing with this type of situation.

Certifications:

- CSA

- Electrical Safety Authority of Ontario

- Member of the Corporation des maîtres électriciens du Québec (CMEQ)

Advantages of Centralizing HVAC Equipment:

- Generates energy consumption savings

- Reduces negative pressure in the building

- Improved temperature control

- Maintenance effectiveness

- Manages equipment via telemetry