Goyen manufactures diaphragm valves in a wide range of configurations to suit a variety of reverse pulse filter designs.

These sophisticated high-precision valves control airflow through the filters for optimal cleaning.

Superior performance, easy maintenance diaphragm valve available with threaded ports (T3), dresser nut ports (DD3) or flange and slide ports (FS3). Outlet at 90° to inlet. 3 Series valves are available as remote pilot valves and may be converted to integral pilot applications through the use of the screw in pilots of the MIP and 3DS series.

Dust collector applications, in particular for reverse pulse jet filter cleaning and its variations including bag filters, cartridge filters, envelope filters, ceramic filters, and sintered metal fibre filters.

Body: Aluminium (diecast)

Seals: Nitrile or Viton (diaphragms reinforced)

Spring: 304 SS

Diaphragm Seat: PA-6 (standard), Viton coated mild steel

Before conducting any maintenance activity on the system ensure that components are fully isolated from pressure and power supplies. Pressure and power should not be reapplied until the valve has been fully assembled. Diaphragm and pilot inspection should be conducted annually.

Integrally piloted valves meet the requirements of:

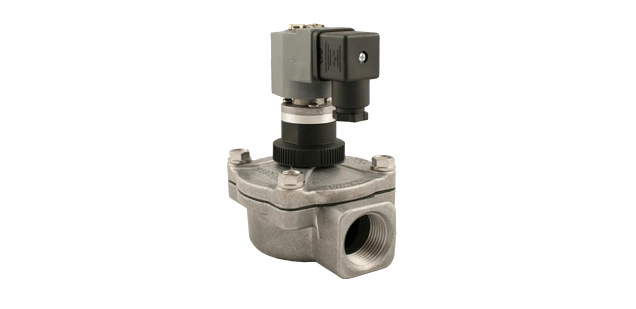

High performance diaphragm valve with threaded ports. Available with integral pilot or as remotely piloted valve. Outlet at 90° to inlet.

Dust collector applications, in particular for reverse pulse jet filter cleaning including bag filters, cartridge filters, envelope filters, ceramic filters, and sintered metal fibre filters.

Body: Aluminium (diecast)

Ferrule: 304 SS

Armature: 430FR SS

Seals: Nitrile or Viton (reinforced)

Spring: 304 SS

Screws: 302 SS

Diaphragm Seat: PA-6 (standard), Viton coated mild steel or High Density PE

Refer to Q Series Solenoid product data sheet for solenoid construction details.

Before conducting any maintenance activity on the system ensure that components are fully isolated from pressure and power supplies. Pressure and power should not be reapplied until the valve has been fully assembled. Diaphragm and pilot inspection should be conducted annually.

Integrally piloted valves meet the requirements of:

High performance diaphragm valve with dresser nut ports. Available with integral pilot or as remotely piloted valve. Outlet at 90° to inlet.

Dust collector applications, in particular for reverse pulse jet filter cleaning and its variations including bag filters, cartridge filters, envelope filters, ceramic filters, and sintered metal fibre filters.

Body and Dresser Nuts: Aluminium (diecast)

Ferrule: 304 SS

Armature: 430FR SS

Seals: Nitrile or Viton (reinforced)

Spring: 304 SS

Screws: 302 SS

Dresser Nut Seals: Nitrile or Viton

Diaphragm Seat: PA-6 (standard), Viton coated mild steel or High Density PE

Refer to Q Series Solenoid product data sheet for solenoid construction details.

Before conducting any maintenance activity on the system ensure that components are fully isolated from pressure and power supplies. Pressure and power should not be reapplied until the valve has been fully assembled. Diaphragm and pilot inspection should be conducted annually.

Integrally piloted valves meet the requirements of:

Very high performance diaphragm valve with flanged inlet port and slide seal outlet port for easy valve installation and removal. Available with integral pilot or as remotely piloted valve. Outlet at 90° to inlet.

Dust collector applications, in particular for reverse pulse jet filter cleaning including bag filters, cartridge filters, envelope filters, ceramic filters, and sintered metal fibre filters.

Body: Diecast aluminium or 316 stainless steel

Ferrule: 304 SS

Armature: 430FR SS

Seals: Nitrile or Viton (reinforced)

Spring: 304 SS

Screws: 302 SS

Outlet Slide Seal: EPDM or Viton

Diaphragm Seat: PA-6 (standard), Viton coated mild steel

Refer to Q Series Solenoid product data sheet for solenoid construction details.

Before conducting any maintenance activity on the system ensure that components are fully isolated from pressure and power supplies. Pressure and power should not be reapplied until the valve has been fully assembled. Diaphragm and pilot inspection should be conducted annually.

Integrally piloted valves meet the requirements of:

Very high performance diaphragm valve designed to be mounted directly into the compressed air manifold. 1″ and 1.5″ models are supplied with outlet pipes to length specified. 3″ model is supplied without outlet pipes.

Dust collector applications, in particular for reverse pulse jet filter cleaning including bag filters, cartridge filters, envelope filters, ceramic filters, and sintered metal fibre filters.

Body and Dresser Nuts: Diecast Aluminium

Ferrule: 304 SS

Armature: 430FR SS

Diaphragm and Seals: Nitrile or Viton (reinforced)

Spring: 304 SS

Screws: 302 SS

Outlet Pipe: Schedule 40 wrought steel zinc passivated Diaphragm Seat: PA-6 (25 & 40MM standard), Nitrile coated mild steel (76MM standard), or Viton coated mild steel (all sizes)

Refer to Q Series Solenoid product data sheet for solenoid construction details.

Before conducting any maintenance activity on the system ensure that components are fully isolated from pressure and power supplies. Pressure and power should not be reapplied until the valve has been fully assembled. Diaphragm and pilot inspection should be conducted annually.

Integrally piloted valves meet the requirements of: