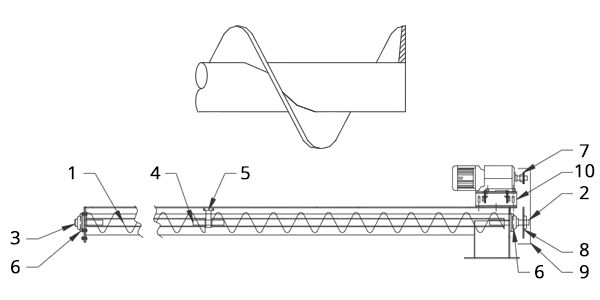

Screw Conveyors are an efficient way of transporting bulk material horizontally or with small angles.

The discharge falls from the hopper into one of the screw conveyor inlet. A rotating screw powered by a motor pushes the material along and within an enclosed shaft from one point to another. At the end of the shaft, the material simply falls into a container or a rotary airlock depending upon the application.