CONFIGURATIONS AND OPTIONS

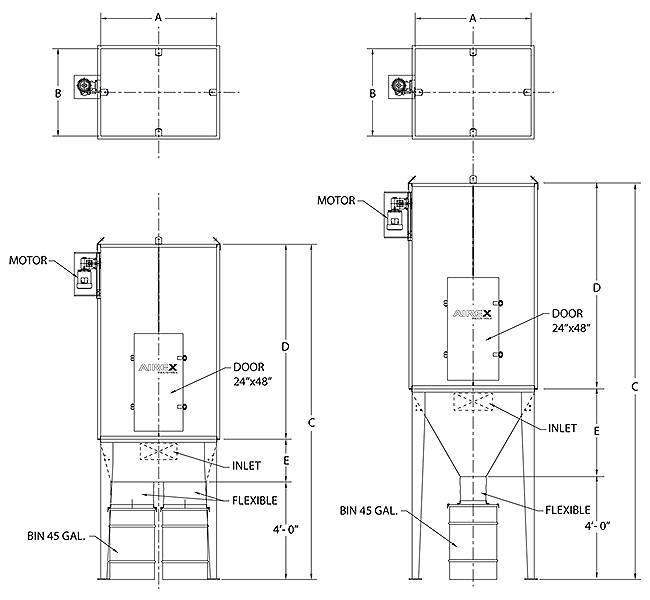

SCS – SCST Model

Recognized for its robust quality manufacturing, the SCS(T) is definitely the least expensive product line among all categories of industrial-rated units. Its compact design is well suited for inside and outside locations with space restrictions.

The SCS(T) may be equipped with a direct or indirect drive whose motor output varies as a function of system static pressure and flow rates within network conduits. In addition, this unit offers filtration surfaces from 100 to 1031 sq. ft.

When exposed to potentially explosive dust, rigid collars are required at hopper & barrel interfaces as a means to ensure air-tight connections within dust collector housings.

Body Height: Filter bags come in two sizes, either 60 or 96 inch lengths.

SCS Model: The SCS comes equipped with a lower hopper that may be connected to a maximum of 4 barrels, thereby extending scheduled maintenance frequencies.

SCST Model: The SCST only requires a single barrel, giving us the opportunity to install a rotary valve. Additional vertical clearance will be needed, nonetheless, to accommodate the higher hopper.

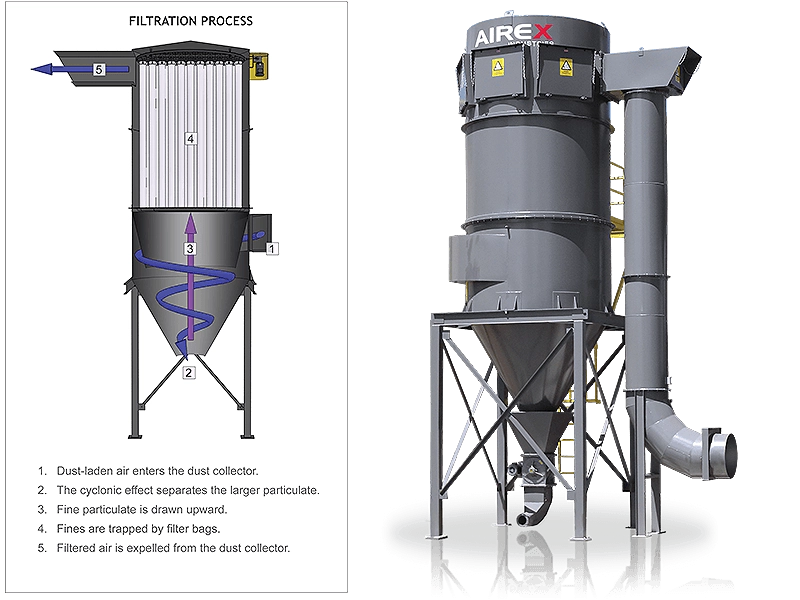

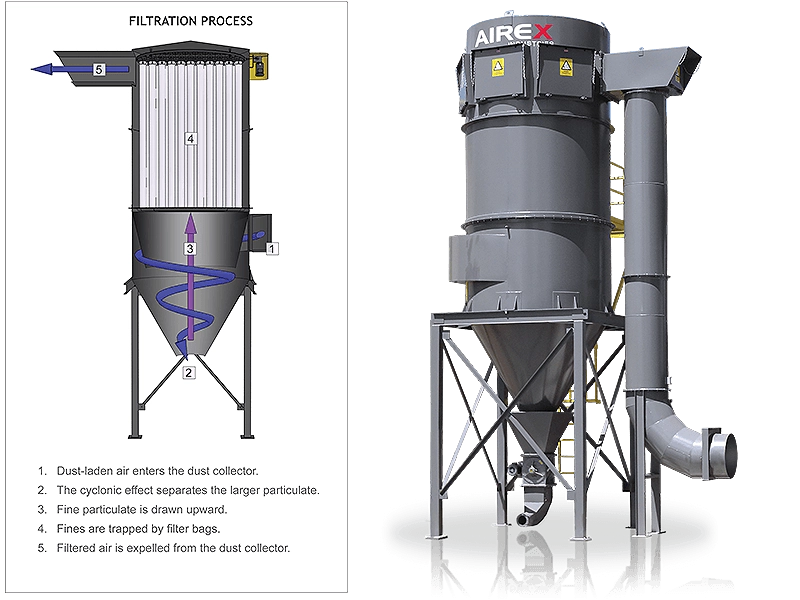

CE Model

The benefits of cyclonic effect technology are well known among customers with large-scale requirements. In response to this need, the CE shaker-type dust collector offers remarkable capacity with high volume filtration. Filtration surfaces range from 1584 to 14007 sq. ft.

Particulate matter at the bottom of the hopper is typically conveyed pneumatically or screw-fed to a container, whose large storage capacity minimizes maintenance.

Collected dust particulate passes through initial filtration, whose centrifugal force separates the heavier fractions that migrate along the walls to the base of the hopper.

The lighter dust is drawn upwards for subsequent (secondary) filtration. At this step of the process, fine particulate is trapped within the cloth mesh of filter bags.

The filtered air meanders on to the shaker dust collector exit to be recirculated within the building or exhausted outside.