HEALTH & SAFETY

Explosive Dust Collection Waits For A Spark In Your Workplace

The dangers arising from dust collection are unfortunately not considered enough. Sadly the risk is real and when vigilance is omitted, serious incidents occur.

Your Safety Is Our Priority

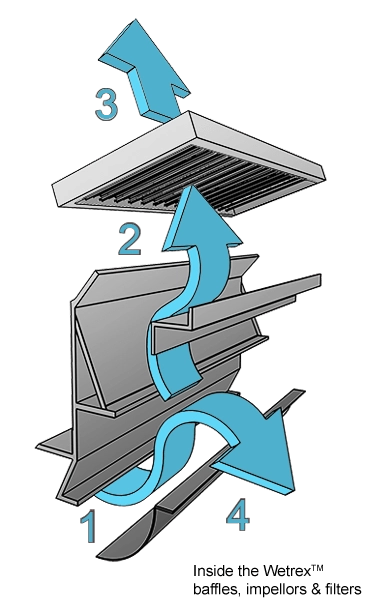

The WetrexTM Series from Airex Industries is a high tech air filtration system which is best used in highly explosive, reactive dust (aluminum and titanium) and oil mist applications. This unit effectively separates dust particles by saturating the air stream with a water vortex while reducing the potential for an explosion.

This customizable, highly efficient, top quality industrial grade unit requires little maintenance. Its simplicity and high efficiency remain its two greatest advantages.

Our central point ducted wet collector offers high capacity, various volumes and the possibility of using a high pressure duct network, a feature many of our competitors do not have.

Tragedies Caused By Dust Explosion

1. Imperial Sugar Company

February 7 2008, Port Wentworth, GA; An unknown source ignited accumulated sugar dust, causing a violent explosion.

2. Hoeganaes Corporation

January 31 2011, Gallatin, TN; fatal flash fire from hydrogen or nitrogen leaking process pipe fueled by combustible iron dust.

3. Hayes Lemmerz International

October 29 2003, Huntington, IN; The company did not identify or control hazards of aluminium dust.

4. West Pharmaceutical Services

January 29 2003, Kingston, NC; accumulated polyethylene dust above the ceiling tiles fueled the explosion.