Variable Air Volume Dust Collection: When Ventilating Means Savings

Did you know that installing a variable air volume dust collection system can generate substantial savings? This automated system also reduces your equipment’s maintenance needs over the long term. Find out how and why!

Variable Air Volume and Fixed Volume, What’s the Difference?

A number of plants use fixed volume air extraction systems. In those cases, the dust is collected using a main duct that directs air from multiple capture points towards the dust collector. A fixed volume fan then does all the work.

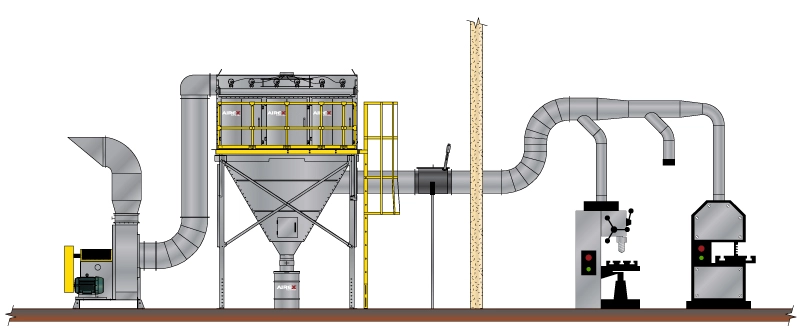

Schematic of fixed volume dust collector

Schematic of fixed volume dust collector

Although this is the best choice in some situations, there are a few negatives with fixed volume dust collection:

- It can be overused It always operates at full capacity, even if some processes are not being used. As a result, it wears out prematurely and requires more frequent repairs that can lead to service outages.

- It results in energy losses If it draws air from an unused workstation, you’re paying to filter non-existent particles. And if that air is then discharged outside, you’re throwing money out the window (after all, you paid to cool or heat that air!)

- It’s noisy A fan running at full speed all the time creates noise pollution for both workers and nearby residents.

This is where the variable air volume drive system comes into play: decentralizing the air intake into several separate ductworks. This automated system makes it possible to close the dampers on the ducts for workstations that are unused. For example, if your plant is running at 50% capacity, the system reduces the intake by 50%. Therefore, you use 50% less energy.

Installing a variable air volume system doesn’t just help you save on your energy bill. With less demand placed on it, the dust collector wears less, thereby reducing maintenance and repair costs. Therefore, this optimal use of the system enables a faster return on investment. Interesting, right?

Who is this Energy-Efficient Dust Collection System For?

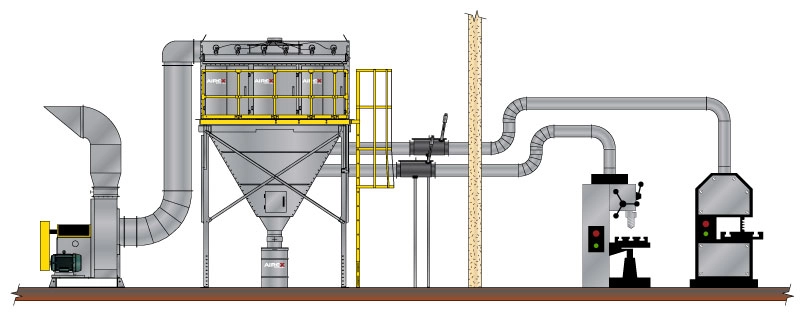

Schematic of variable air volume dust collector

Schematic of variable air volume dust collector

Variable air volume can be chosen for various reasons; here are six of them.

- Plant expansion or increased production. If your existing dust collector has reached maximum capacity, our team could decentralize the collection system and incorporate a variable-frequency drive controller on the fan’s motor. This way, the load removed from the dust collector can be assigned to the new processes. A good way to save on the energy bill without having to change everything.

- Refurbishing or replacing an existing system. If your system is at the end of its life, replacing it with a variable air volume unit will provide you with a better return on investment.

- Building a new plant with a new system. The variable air volume will enable you to adjust the intake to meet the growing needs of your plant.

- Plant with multiple capture points whose average usage rates are below 50%. The variable air volume will then enable you to see a real difference on your energy and maintenance bills.

- Company that doesn’t recirculate the air. Regardless of the reason, this air loss is energy intensive. A more efficient system will enable you to mitigate the impact.

- Plant with limited electrical power. In this case, the variable air volume system is a good solution because it doesn’t operate at full capacity, thereby reducing the draw at the electrical panel.

How is a Variable Air Volume System Installed?

Our experts start by measuring the usage of the workstations, the tasks performed by the employees and their duration, which enables them to accurately identify your facility’s dust-collection needs.

An engineer then analyzes the usage over time and creates simulation models. That data enables him to determine the foreseeable reduction in electricity use. That way, he can calculate the return-on-investment period of the variable air volume versus fixed volume system.

If the result is significant, we modify the design of the ductwork, while complying with the flow rates required by the NFPA. We can even suggest some grants that can help you carry out your project.

If the nature of your process allows, opting for variable air volume dust collection is definitely a viable solution! Want to learn more about this system? Our experts are always available.

Get in touch with our experts!